About UsSTS Targets is a home based small business located in Lewiston South Australia.

Our mission statement is to provide exemplary customer service and high quality products to Australian Shooters. With a background in Production Engineering, and as a keen hunter rifle and handgun shooter, Shaun @ STS is always on the lookout for new and innovative ways of improving the sports of target shooting and hunting. This is demonstrated by STS’s patented MoA ruler which combines everyday shooting concepts and innovative thinking to produce a cheap and useful product for Aussie targets shooters and hunters alike. For all enquiries or to put forward your idea for a shooting accessory you would like to see on the market, please contact us! |

Frequently Asked Questions

Why shoot steel targets? |

Unlike paper targets, when you hit a steel target the feedback is immediate, steel target gongs make an audible sound upon each bullet hit notifying you and your buddies you’ve hit your mark. Steel targets provide a visual hit confirmation via removal of the paint and the swinging of the target. They excel at long range shooting were spotting scopes and paper targets become ineffective.

|

What are STS targets made from? |

Unless stated otherwise, all STS Hardened Steel Shooting targets are manufactured from laser cut, Bisalloy Steel Group Limited’s BISPLATE® 500 (also referred to as Bis500 or Bisalloy 500) grade of through hardened, abrasion resistant steel plate (Ref: www.bisalloy.com.au).

BISPLATE® 500 is a commercially available hardened steel plate which is of equivalent hardness to military grade high hardness armor (HHA) plate. BISPLATE® is a brand name for Quenched and Tempered (Q&T) Abrasion Resistant (AR) steel. However it is most commonly referred to as ‘Bis’ or ‘Bisalloy’. Other steel manufacturers refer to this style of hardened steel plate as either Q&T (Quenched and Tempered, i.e Q&T500) or AR (Abrasion Resistant, i.e AR500) plate. The key piece of information in the material titles listed above is the Brinell Hardness Number (BHN), which in these cases are 500. This is the ‘typical’ surface hardness of the material, where the higher the number the harder the steel, e.g.: Grade 320 = Min 320 to a Max of 360 BHN Grade 400 = Min 370 to a Max of 430 BHN Grade 450 = Min 450 to a Max of 475 BHN Grade 500 = Min 447 to a Max of 543 BHN (Comparatively common GR250 Mild Steel plate (E.g. AS/NZS 3678 -250) has a typical BHN range of 120 to 160). Quench and Tempering refers to the process of hardening materials by heating it to a certain temperature and cooling it down again at a certain rate. Due to thermal hardening, heating of the material during the process of oxy-cutting, angle grinding, welding etc. can detrimentally alter the hardness of the material. The best methods to cut thermally hardened steel are Water Jet cutting, laser cutting & plasma cutting in that order. Bis500 hardened steel is able to be welded by conventional low hydrogen methods, however process controls must be put in place to minimize the risk of the heat affected zones cracking. For further information on welding BISPLATE® material refer to the manufacturer’s website at www.bisalloy.com.au. |

How are STS Targets Finished? |

STS targets are finished in either an enamel based gloss white paint or gloss white powder coated. They are supplied with a bulls eye decal indicating the grade of steel used for that particular target.

Note: The white finish and decal will be removed with each bullet impact, providing a visual indicator (via absence of paint) for the position of the bullet strike. The quantity of the finish removed is very much subject to the calibre and type of projectile used, as well as its angle of incidence with the target plate. |

What paint do I use to re-paint my target? |

When it comes to repainting your target, STS recommends “Wattyl® KillRust Epoxy Gloss Enamel Top Coat” in White as a good all-in-one product to use due to is high adhesion to steel. It is available in 300g aerosol cans. Being an all-in-one product it does not require a primer or undercoat.

If complete refinishing is desired, it is recommend the target be stripped of paint using an angle grinder with and abrasive wire wheel/cup attachment. |

What can I mount or hang my targets off of? |

STS targets can be mounted in numerous ways. These targets are most effective when free-swinging in mid-air. This can be achieved by suspending the targets from chains, cable or steel rods/arms.

A more hardy mounting method (less susceptible to damage due to stray bullets) is to use thick sections of rubber, such as second hand conveyor belt about 9-12mm thick. This can be used in place of chains by drilling a hole in the rubber belt and securing the target to it with high tensile steel bolts and large flat washers. It is recommended to use nyloc nuts in this application as the shock from bullet strikes can work standard nuts loose over time. Suspending STS targets in mid-air allows the energy of the projectile to be better absorbed by swinging the target and in doing so extending its life. Suspension it also permits the sound of the bullet impact to resonate and be heard at a distance. A convenient and portable solution to target mounting is by utilising an STS Steel Target Frame or for a more permanent setup a pair of STS Dropper Toppers. Other possible mounting options include, hung from a tree branch or off a free standing frame such as a saw horse. As with all target shooting, be mindful of your backdrop and only deploy targets in safe positions for both yourself everyone around you. |

What is a MoA or Minute of Angle? |

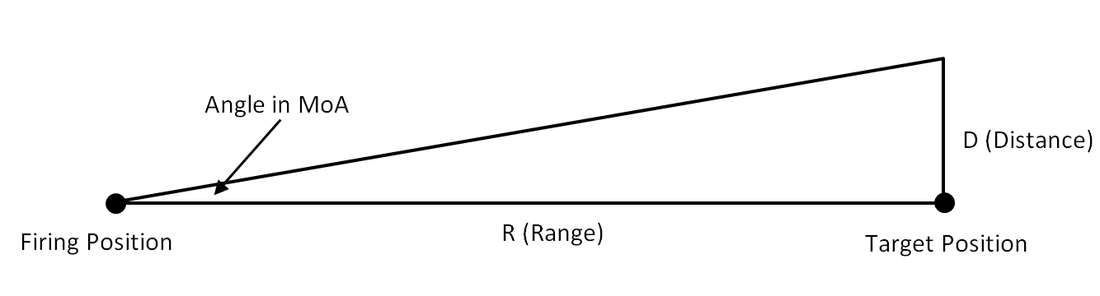

A common unit of measure in firearm shooting is the “Minute of Angle” or “Minute of Arc” which is generally referred to as the acronym “MoA”. One MoA is defined by 1/60th of a degree of arc where a full circle contains 360 degrees of arc.

As such 1 MoA = 0.01666666… degrees Due to MoA being an angular measurement, the distance subtended by 1 MoA increases linearly with the distance between the origin (firing position) and destination (target). The distance ‘D’ at which one Minute of Angle subtends at range ‘R’ is represented by the following trigonometric equation:

D = Tan(1/60)*R Firearm sights often contain adjustments in 1/4th or 1/8th MoA click values. As such 4 clicks of a 1/4th MoA sight correlates to 1 MoA and likewise, 8 clicks of a 1/8th MoA sight correlates to 1 MoA. Occasionally sight manufacturers use ¼ Inch @ 100 yards click values in place of 1/4th MoA. This is a close approximation of 1/4th MoA sight as 0.25 MoA at 100 yards = 0.2617 inches compared to 0.25 inches. The difference in these conventions can become significant for longer range shooting. At 1000 yards 40 clicks (10 MoA) of a true MoA sight will result in a shift of 104.7 inches compared to 100.0 inches for 40 clicks of a ¼” @ 100yard sight. |

Do you make custom targets? |

If you have a special target request please contact us.

Custom targets are available on a made to order basis, however due to the low quantity manufacture prices are generally more expensive than similar sized STS targets. A minimum order value of $250 (plus shipping) is applicable for custom target designs. Typical turnaround time for custom order targets is 3-4 weeks. |

SAFETY

Firearms shooting is an inherently dangerous activity, as such all safety precautions must be considered and executed (if reasonably practicable) when both handling and utilising firearms. Required Safety Measures for Steel Target shooting:

* Always wear ANSI approved safety glasses with side shields to protect your eyes.

* Always wear shooting rated hearing protection to protect your hearing.

* Always support targets on a free swing target frame and ensure the steel plate is angled towards the shooter no less than 15degree off vertical.

* Bullets create a splash cone of lead and jacketed particles after hitting steel targets that can travel greater than 20 metres for handguns and greater than 75 metres for rifles. This splash zone can reach up to a 25-degree cone angle in a 360-degree direction from the surface of the impacted steel target.

* Only use frangible ammunition when shooting steel targets.

* Recommended minimum distances from steel targets to shooter are 25 metres for pistols and 150 metres for rifles. Spectators should stand 10 metres behind the shooter.

* Use only properly constructed firing range with adequate backstop and adequate down range safety area.

* Always locate the steel targets as close to the backstop as possible.

* Discontinue the use of any close range steel target that has surface craters caused by wear or improper ammunition use on the steel target impact area. The steel target impact surface must be smooth and flat to safely use steel targets.

* Never shoot hardened, steel core or Armor Piercing (AP) ammunition at any steel target

* Never shoot any type of shotgun slug at any steel target.

* Always wear ANSI approved safety glasses with side shields to protect your eyes.

* Always wear shooting rated hearing protection to protect your hearing.

* Always support targets on a free swing target frame and ensure the steel plate is angled towards the shooter no less than 15degree off vertical.

* Bullets create a splash cone of lead and jacketed particles after hitting steel targets that can travel greater than 20 metres for handguns and greater than 75 metres for rifles. This splash zone can reach up to a 25-degree cone angle in a 360-degree direction from the surface of the impacted steel target.

* Only use frangible ammunition when shooting steel targets.

* Recommended minimum distances from steel targets to shooter are 25 metres for pistols and 150 metres for rifles. Spectators should stand 10 metres behind the shooter.

* Use only properly constructed firing range with adequate backstop and adequate down range safety area.

* Always locate the steel targets as close to the backstop as possible.

* Discontinue the use of any close range steel target that has surface craters caused by wear or improper ammunition use on the steel target impact area. The steel target impact surface must be smooth and flat to safely use steel targets.

* Never shoot hardened, steel core or Armor Piercing (AP) ammunition at any steel target

* Never shoot any type of shotgun slug at any steel target.

DISCLAIMER

STS STEEL TARGETS ARE INTENDED FOR A SPECIFIC USE AS PART OF AN INHERENTLY DANGEROUS ACTIVITY. THESE PRODUCTS MUST BE USED IN THE INTENDED MANNER ONLY AND IN DIRECT COMPLIANCE AND ACCORD WITH THE ENCLOSED INSTRUCTIONS. EVEN SO, INJURY MAY OCCUR. DUE TO THE INHERENTLY DANGEROUS NATURE OF THE ACTIVITY, NO WARRANTY OF THESE PRODUCTS IS GIVEN OTHER THAN THEY WILL PERFORM AS DESIGNED IN THEIR INTENDED USE. ANY ALTERATION OF THESE PRODUCTS OR THEIR USE SHALL VOID ALL WARRANTIES EXPRESSED OR IMPLIED. OTHER THAN THE FOREGOING, THERE ARE NO WARRANTIES OR GUARANTIES GIVEN NOR ANY LIABILITY ASSUMED BY THE MANUFACTURER IN THE USE OF THESE PRODUCTS. ALL RISK OF INJURY IS ASSUMED BY AND SHALL PASS TO THE PURCHASER OF THESE PRODUCTS OTHER THAN THOSE ITEMS SPECIFICALLY STATED ABOVE.

THE LAWS IN AUSTRALIA VARY FROM STATE TO STATE. PLEASE CHECK WITH YOUR LOCAL FIREARMS AUTHORITY REGARDING THE LAWS IN YOUR STATE. WE ACCEPT NO RESPONSIBILITY FOR ILLEGAL OR IRRESPONSIBLE USE OF OUR EQUIPMENT BY ANY INDIVIDUAL OR ORGANISATION.

THE LAWS IN AUSTRALIA VARY FROM STATE TO STATE. PLEASE CHECK WITH YOUR LOCAL FIREARMS AUTHORITY REGARDING THE LAWS IN YOUR STATE. WE ACCEPT NO RESPONSIBILITY FOR ILLEGAL OR IRRESPONSIBLE USE OF OUR EQUIPMENT BY ANY INDIVIDUAL OR ORGANISATION.